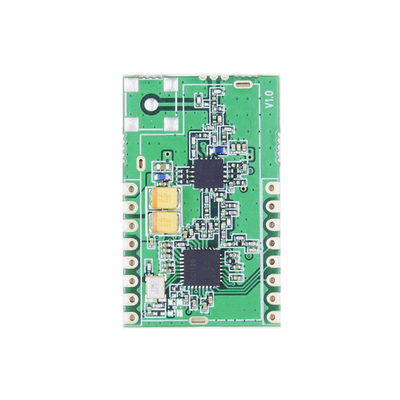

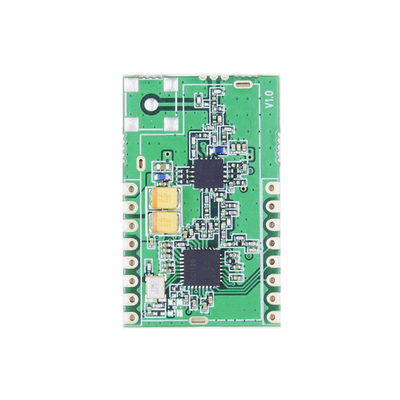

Application process of RTK radio network modeWith the upsurge of industry development, radio Module The expressive force in the market has also been very good, bringing many brand-new high-quality experiences to users. https://www.hkulike.com/

1, instrument erection

Complete the hardware erection and configuration of the reference station and mobile station, and build the hardware environment for the operation.

2. New projects

Create engineering, configure basic information such as parameters and coordinates, and complete the data foundation needed for the operation.

3. Find the conversion parameters

Match the plane coordinates required by the project with the default latitude and longitude coordinates, and directly obtain the required target reference frame coordinates in the operation. /4, single point correction

Input the known plane coordinates of the measuring point and correct the parameter differences between different coordinate systems. (It can be skipped after parameter calculation, but it needs to be corrected every time the base station restarts.)

4. Check the known points

Measure at known points to confirm whether the parameter transformation between different coordinate systems is accurate and effective.

5, measurement and lofting

Carry out survey or lofting operations in the operation area to obtain the target results.

6. Data export

Export data from the notebook and copy it to the computer for office processing.

Use process of RTK radio mode

1, the erection of reference stations

Load the battery and turn it on.

Open the project star in the notebook and connect to the host through the Bluetooth Manager.

Use “Host Settings” to set the host as “base station” and the host data link as “radio station”, set the corresponding radio channel, select the appropriate data format (such as RTCM32) in “Reference Station Settings”, and click “Start the base station” after obtaining the coordinates of the base station.

When the data light flashes every second, it indicates that the reference station has been started successfully.

2. Set up the mobile station

Similar to the reference station, the host is set as “mobile station” and the host data link is set as “radio station”, and the radio channel corresponding to the reference station is set.

When the data light of the mobile station flashes every second and reaches a fixed solution, it indicates that the mobile station is working normally.

3. Parameter setting

New Project: After the solution status is fixed, click “Project” and “New Project” and enter the project name.

Antenna Height Setting: Click “Configuration” and “Engineering Settings” and enter the correct antenna height.

Coordinate System Settings: Click Configure, Coordinate System Settings and Add, and enter the name of the parameter system (set at will). Select the ellipsoid name as required, and enter the actual local central meridian, and use the default values for other parameters.

4. Find the conversion parameters

Click “Measure” and “Point Measure” to collect the coordinate information of two known points A1 and A2 in turn.

Click “Input”, “Calculation of Conversion Parameters” and “Add”, input the known plane coordinates of point A1, “OK” and “Select a point from the coordinate management library”, select the newly measured point A1, then complete the entry of point A2 in the same way, click “Save”, enter a user-defined file name, and click “Apply” after checking that the horizontal and elevation accuracy are correct, and then assign the parameter values to the current project.

After the conversion is completed, the information of the third known point A3 is collected for verification.

5, single point correction

Every time the reference station is restarted, the mobile station should make a single point correction.

Click “Input”, “Calibration Wizard” and “Reference Station Erected at Unknown Point” to erect the mobile station at a known control point. Enter the known plane coordinates and pole height of the mobile station, click “Calibration” and “OK” after the bubble is centered, and the calibration work is completed. After the calibration is completed, it should be checked at another known control point.

6. Measure

After completing the above steps, point measurement and lofting can be carried out.

Application process of RTK radio network mode

1, the erection of reference stations

Insert the SIM card, load the battery, and start the machine.

Open the project star in the notebook and connect to the host through the Bluetooth Manager.

Use “Host Settings” to set the host as “base station” and the host data link as “network”.

Set the network mode. Customize “Host Settings”, “Network Settings”, “Add” and “Name”, select EAGLE for “Mode”, GPGGA/CDMA for “Connection”, fill in cmnet for “APN”, enter the IP address and corresponding port, set the user name and password, and generally set the access point as the base station host body number to facilitate identification and prevent duplication. Click “OK” after setting.

Select an appropriate data format (such as RTCM32) in “Reference Station Settings”, click “Start Base Station” after obtaining the coordinates of the base station, and when the data light flashes every second, it indicates that the reference station has been started successfully.

2. Set up the mobile station

In a way similar to the base station, set the host as a mobile station and the data link of the host as a network. According to the setting of the base station, select “NTRIP-UDS” as the Mode, enter the corresponding IP address, port, user name, password and access point, and click “OK” and “Connect” until the GPGGA data is successfully uploaded.

When the data light of the mobile station flashes every second and reaches a fixed solution, it indicates that the mobile station is working normally.

3. Parameter setting

New Project: After the solution status is fixed, click “Project” and “New Project” and enter the project name.

Antenna Height Setting: Click “Configuration” and “Engineering Settings” and enter the correct antenna height.

Coordinate System Settings: Click Configure, Coordinate System Settings and Add, and enter the name of the parameter system (set at will). Select the ellipsoid name as required, and enter the actual local central meridian, and use the default values for other parameters.

4. Find the conversion parameters

Click “Measure” and “Point Measure” to collect the coordinate information of two known points A1 and A2 in turn.

Click “Input”, “Calculation of Conversion Parameters” and “Add”, input the known plane coordinates of point A1, “OK” and “Select a point from the coordinate management library”, select the newly measured point A1, then complete the entry of point A2 in the same way, click “Save”, enter a user-defined file name, and click “Apply” after checking that the horizontal and elevation accuracy are correct, and then assign the parameter values to the current project.

After the conversion is completed, the information of the third known point A3 is collected for verification.

5, single point correction

Every time the reference station is restarted, the mobile station should make a single point correction.

Click “Input”, “Calibration Wizard” and “Reference Station Erected at Unknown Point” to erect the mobile station at a known control point. Enter the known plane coordinates and pole height of the mobile station, click “Calibration” and “OK” after the bubble is centered, and the calibration work is completed. After the calibration is completed, it should be checked at another known control point.

6. Measure

After completing the above steps, RTK radio station can carry out point measurement and lofting.