When considering the purchase of an injection mold, especially for mass production of plastic parts, it¡¯s essential to understand the total cost involved. How much does an injection mold cost? For those looking to buy plastic injection molds from China, estimating the overall cost includes several components: mold design, materials, machining, surface treatment, sampling, shipping, and duties. Here is a breakdown of the key cost factors:I think Mold manufacturing It will definitely become a leader in the industry and look forward to the high-end products. https://bfymold.com/services/injection-molding/

1. Mold Design Costs

Mold design typically accounts for about 10% of the total injection mold cost. For a simple part, Design for Manufacturability (DFM) can take 1-2 days, and 3D mold design may take 2-3 days. More complex molds can take weeks to design. The design phase is critical as it significantly impacts the overall cost and quality of the mold. Skilled designers can optimize costs while ensuring the mold meets all specifications.

Mold Design Cost

Mold Design Cost

2. Material Costs

Materials represent 20-30% of the total injection mold cost and include several components:

Die Steel

For larger molds, the quality of the steel is crucial as it determines the mold¡¯s durability and the number of cycles it can endure before needing repairs. It¡¯s advisable not to compromise on steel quality despite the cost.

Mold Base

This typically uses lower-grade steel. However, the mold supplier must provide a cost-effective mold base with quick delivery and minimal processing errors.

Mold Base

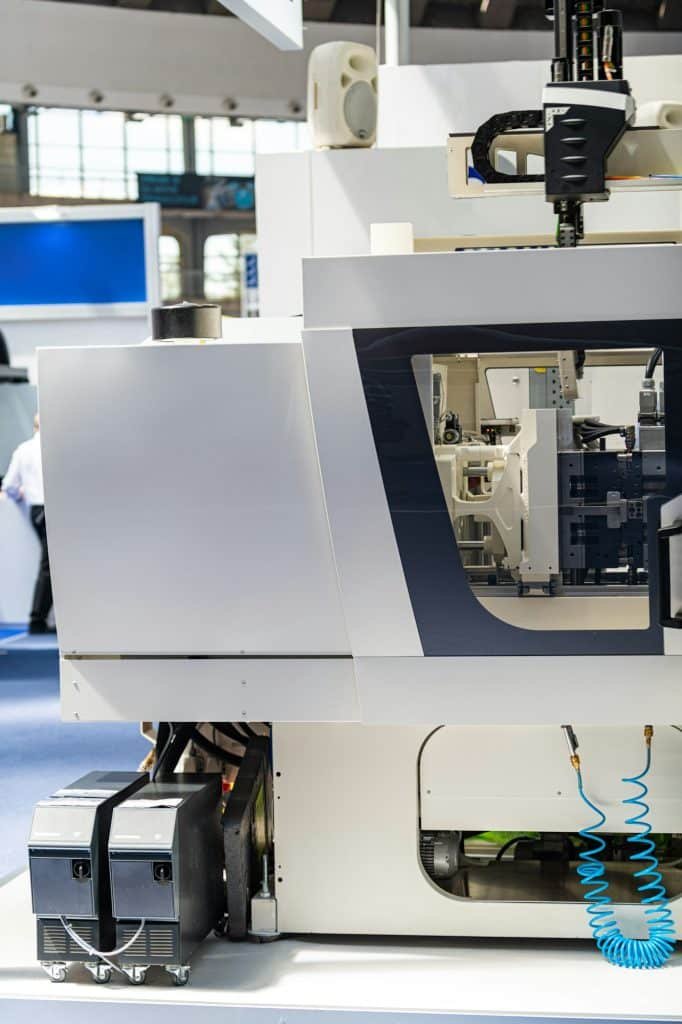

Injection Mold

Mold Accessories and Assemblies

This includes components like ejector pins, locks, springs, cooling line connectors, cycle counters, and safety switches.

EDM Electrode

Depending on mold complexity, Electrical Discharge Machining (EDM) might be required, especially for molds with intricate details and deep grooves. The choice between graphite and copper electrodes affects both the cost and the mold quality.

CNC Milling

CNC Milling

Plastic Resin

Mold validation often requires 2-3 rounds of sampling, which involves preparing the specified plastic resin in advance based on the part weight and sample size.

3. Processing Costs

Processing costs account for 20-30% of the total injection mold cost. Key processes include CNC machining, EDM, wire cutting, milling, grinding, and drilling. Maintaining high quality while controlling costs requires significant investment in advanced machinery and skilled labor, making this a major competitive factor for mold manufacturers.

4. Surface Treatment Costs

Standard surface treatments such as polishing to SPI-SPE B/C standards or EDM texturing are relatively inexpensive. However, specialized finishes like mirror polishing or unique textures can add significantly to the cost, depending on the specific requirements.

Surface Treatment Services

Surface Treatment Services

5. Sampling Costs

Sampling constitutes about 3-5% of the injection mold¡¯s total cost. New molds typically require 2-3 rounds of proofing to ensure quality and fit. Effective mold manufacturers minimize sampling time and cost through superior design, processing, and assembly.

6. Freight Costs

If the mold is manufactured in one location and used in another, shipping costs must be considered:

Air Freight:

Costs range from $6-8 per kg. For shipments under 300 kg, express services are recommended; above 300 kg, air freight becomes more economical.

Sea Freight: Starting at approximately $700, sea freight is suitable for bulk shipments.

Rail Freight: Faster than sea freight but sometimes less reliable, with costs starting around $600.

For shipping, it¡¯s advisable to use a single shipping agent for door-to-door service to avoid complications and additional costs.

Injection Mold Freight Costs

Injection Mold Freight Costs

7. Duties and Taxes

Customs duties and taxes vary by region and can impact the overall cost. It¡¯s recommended to consult with a local shipping agent for specific advice on applicable taxes and duties.

By understanding these cost components, you can make informed decisions when purchasing injection molds, especially when sourcing from different regions like China.