In the world of film and television production, reliable power is critical. From lighting rigs to sound equipment, everything requires a stable and efficient power source. That¡¯s where Pro Power Distro comes into play. These power distribution systems are designed to handle the unique demands of film and TV sets, ensuring smooth operations, uninterrupted shooting, and above all, safety. This blog explores the essential role that Pro Power Distro plays in the entertainment industry and why it¡¯s vital for any professional production team.So we can draw a preliminary conclusion, power distribution box price,power distribution box manufacturers,power box factory It is helpful to the needs of the industry market and social development. https://sxpowercase.com/product-category/all-product/power-distribution-boxes/

Why Power Distribution Matters in Film and TV Production

Film and TV production sets are complex environments with high-power needs. Unlike standard events or industrial setups, production sets require consistent and distributed power to multiple locations on set. From cameras and lighting to sound and effects systems, having a centralized power distribution system, such as a Pro Power Distro, ensures that all components receive the necessary electricity without the risk of power overloads or failures.

Without a reliable power distribution solution, productions may face sudden blackouts or equipment damage, leading to costly delays. A well-implemented power distribution box streamlines the process by delivering power precisely where it¡¯s needed, keeping everything running smoothly.

How Pro Power Distro Ensures Reliable Power On-Set

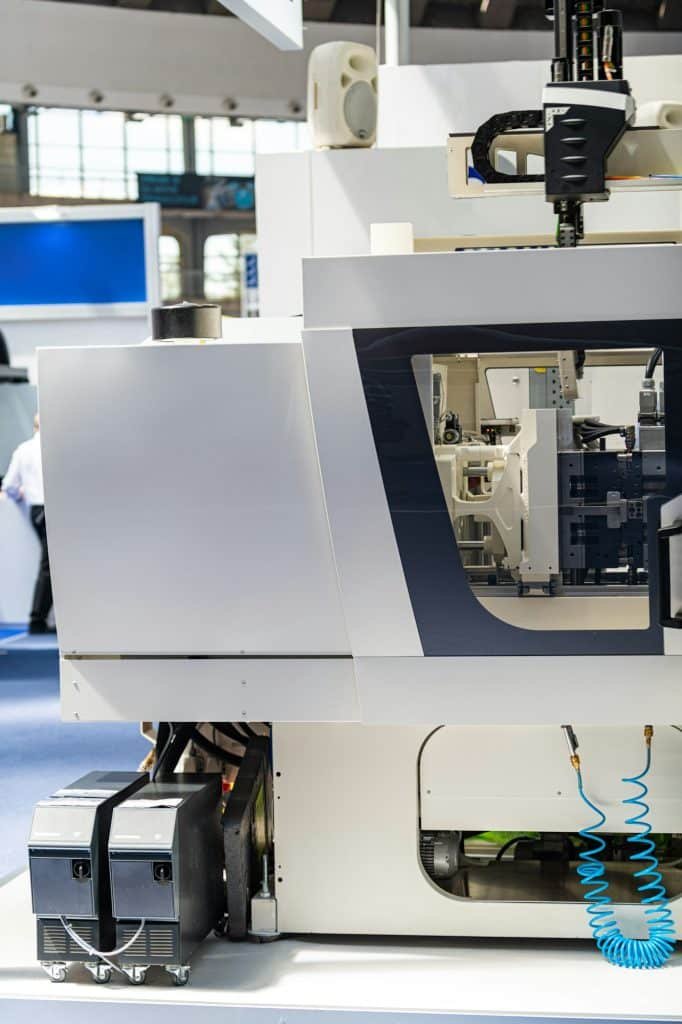

Pro Power Distro systems are designed to handle a range of power loads, which makes them ideal for film and TV productions. These systems convert high-voltage electricity into the lower voltages that specific equipment may require. Moreover, distribution panels prevent circuits from overloading, ensuring consistent performance across all equipment.

One of the primary benefits of using Pro Power Distro on set is its flexibility. A typical film set might move from one location to another, requiring the power distribution system to adapt quickly. Mobile power distros are perfect for this, offering portability and quick setup, so the production crew can relocate without losing time.

Safety Benefits of Using Pro Power Distro in Film and TV

Safety is paramount in any production setting, and this is another area where Pro Power Distro shines. Electrical systems can pose a serious hazard if not managed properly, particularly on fast-paced sets with lots of movement and equipment.

Power distribution systems help prevent overloads by distributing the electrical load evenly across multiple circuits. Each circuit is protected by circuit breakers, so if a fault occurs, only the affected equipment shuts down, preventing widespread outages or hazards like fires.

Additionally, Pro Power Distro systems come equipped with surge protection features, which protect delicate equipment, such as cameras and audio recording devices, from damage caused by power spikes. This ensures the longevity of equipment and reduces the risk of costly replacements.

Types of Pro Power Distro Systems for Film and TV Productions

There are various types of Pro Power Distro systems available, each suited to different production needs. For small to medium-sized productions, a portable power distribution box may suffice. These units are compact and easy to transport, offering enough capacity for smaller setups.

For larger film shoots, a three-phase power distribution box is often necessary. These systems can handle the high electricity demands of large-scale lighting rigs and heavy-duty equipment. They provide a more stable power supply and can be configured to meet the specific voltage needs of various gear.

Another common option for film and TV productions is the custom power distro box. This allows production teams to tailor their power distribution system to meet the unique demands of their specific shoot. Whether it¡¯s a large studio setup or an outdoor location, a customized distribution box ensures that power is delivered safely and efficiently.

SX: Leading Provider of Pro Power Distro Solutions

When it comes to ensuring reliable power on set, the quality of your Pro Power Distro system makes all the difference. SX offers state-of-the-art power distribution solutions designed specifically for the unique demands of film and TV production. With customizable options and high-quality components, SX¡¯s power distribution systems ensure seamless and safe power delivery, no matter the size or scale of your production.

SX¡¯s power distribution systems are designed to be durable, reliable, and easy to use, making them a trusted choice for professionals in the film and TV industry. Whether you need a portable setup for on-location shoots or a large-scale distribution panel for studio work, SX has a solution tailored to your needs.

Conclusion

In the fast-paced world of film and television production, having reliable and safe power distribution is essential. Pro Power Distribution systems provide the flexibility, safety, and efficiency required to keep your production running smoothly. From protecting expensive equipment to ensuring consistent performance across all devices, a quality power distro system is the backbone of any successful shoot. Choose SX for your power distribution needs and ensure your next production is powered to perfection.