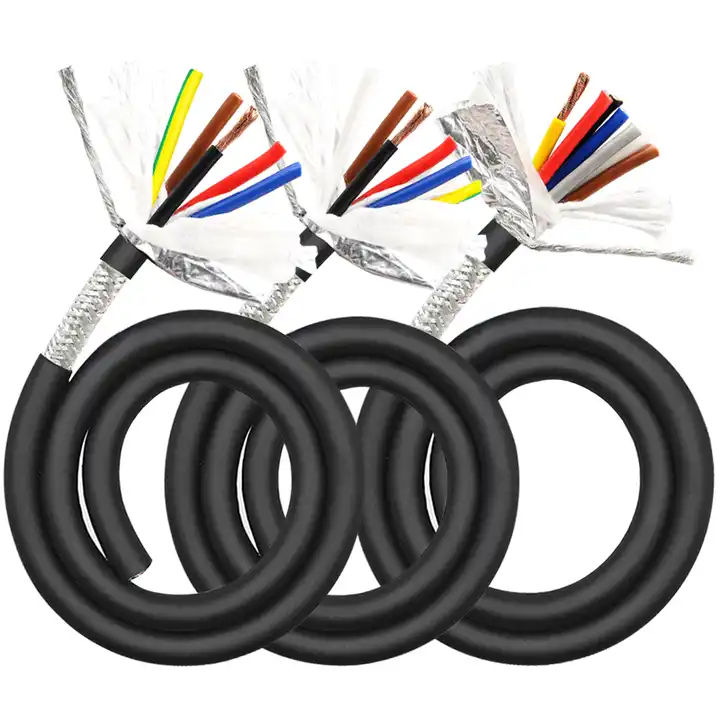

Is it better to have a multi-core cable or a single-core cable? The difference between single-core cables and multi-core cables. Power cables are generally divided into single-core, double-core and three-core cables. Among them, single-core cables refer to cables with only one conductor in one insulation layer, while double-core cables refer to cables with two conductors in one insulation layer. In fact, both have their advantages and disadvantages. For example, when the line of a single-core cable is long, when the control circuit with a large current is used or when it is laid in water, in order to prevent or reduce the middle connector, or when single-core cables have better comprehensive safety engineering than multi-core cables, single-core cables can be used.for a long time multicore cable price It has an extraordinary development speed, and I believe that the future will be as overwhelming as ever. https://www.linkcablecn.com

Is it better to have a multi-core cable or a single-core cable?

1. From the current point of view, the current passing through a multi-core cable with the same cross-sectional area is relatively larger than that of a single-core cable, and the load is large.

2. From the perspective of power loss, the two ends of the single-core cableare directly grounded, and the metal shielding layer of the cable may also generate circulating current that can reach the current carrying capacity of the cable, which wastes power and forms loss. Multi-core cables are generally three-core cables, because during the operation of the cable, the sum of the currents flowing through the three cores is zero, and there is basically no induced voltage at both ends of the cable metal shielding layer.

3. From the perspective of cost, among the wires of the same cross-sectional area, the cost of single-core cables is cheaper than that of multi-core cables, and multi-core cables are slightly more expensive.

4. From the perspective of installation, single-core cables appear harder when passing through pipes, while multi-core cables are softer and easier to wire.

Multicore Flexible Cables.jpg

Multicore Flexible Cable.jpg

The difference between single-core cables and multi-core cables

2-core cables: When the neutral line of 1kv and below power supplies is directly grounded, the number of cable cores of the single-phase control circuit should be 2-core cables when the maintenance line and the neutral point share the same conductor. For control circuits that can be powered by DC, 2-core cables should be used.

3-core cable: When the neutral line of 1kv and below power supply is directly grounded, the number of cable cores of the single-phase power control circuit is: When the protection line and neutral point are separate, it is advisable to use a 3-core cable.

4-core cable: 1kv and below 4-core cable (3+1 cable), in which the fourth core is used as a grounding protection, and also carries the unbalanced current and short-circuit capacity of the power supply system. (To learn more about cable technology, please click here, a lot of dry goods are waiting for you) Its size is determined by the unbalanced current and short-circuit capacity, but generally cannot be less than 1/2 of the phase line.

5-core cable: 1kv and below three-phase four-wire distribution room system, some electrical equipment distribution lines with higher safety requirements, and some communication centers and automation equipment that must ensure power safety and anti-interference grounding, it is advisable to use 5 copper core cable TN-C distribution room system, so that the protection line (PE line) and neutral point (PN line) are independent, and the cable core section is generally 3 large and 2 small or 4 large and 1 small or 5 large.

Multicore Flexible Cable supplier.jpg

The difference between 4-core cable and 3+1 core cable: 1kv and below three-phase four-wire distribution room system, when the protection line and neutral point share the same conductor, 4-core cable should be used, and the method of 3-core cable plus single-core cable to form a circuit cannot be used, or even the method of directly using the metal sheath or armored cable layer of 3-core cable as the neutral point. Otherwise, when the 3-phase current is unbalanced, it is equivalent to the operation of a single-core cable, which is easy to cause DC interference.