In an era where sustainability is more than just a buzzword, making thoughtful choices about packaging can have a significant impact. Custom recycled poly mailers are leading the charge in eco-friendly packaging solutions, and here¨s why they¨re a game changer for both businesses and the planet. If you¨re considering recycled mailing bags bulk or recycled mailing bags wholesale, understanding their environmental benefits might just make your decision easier.As it happens, many people are killed biodegradable mailing bags And bring more benefits, make it flourish, and promote the industry greatly. https://biodegradable-gd.com

1. Cutting Down on Plastic Waste

Every year, millions of tons of plastic end up in landfills and oceans, causing harm to wildlife and ecosystems. Custom recycled poly mailers offer a powerful way to tackle this issue. Made from recycled plastic, these mailers help reduce the volume of waste by reusing materials that would otherwise contribute to pollution. By choosing recycled mailing bags bulk, you¨re directly supporting efforts to divert plastic from landfills and cut down on environmental damage.

2. Saving Valuable Resources

Producing new plastic items requires a lot of resources, including energy and raw materials like petroleum. In contrast, custom recycled poly mailers are created from recycled plastic, which uses less energy and fewer resources. This not only conserves valuable materials but also reduces the overall environmental footprint of your packaging. Opting for recycled mailing bags wholesale helps lower the demand for new plastic production and supports more sustainable practices.

3. Reducing Carbon Emissions

The production of recycled plastic emits fewer greenhouse gases compared to manufacturing new plastic. Custom recycled poly mailers help lower carbon emissions by minimizing the energy needed for production and reducing the transportation of raw materials. This makes your packaging choice a small but impactful step towards combating climate change. Choosing recycled mailing bags can help your business contribute to a greener future.

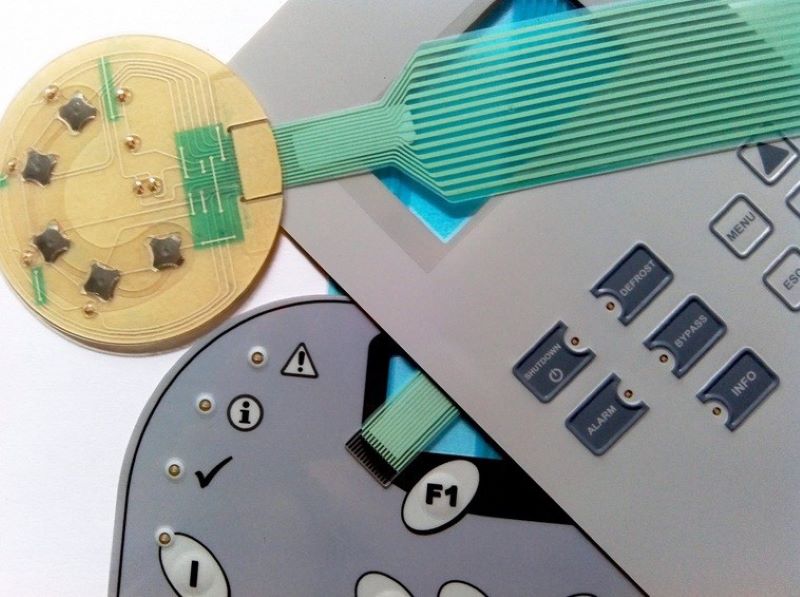

custom compostable mailing bags

4. Fostering a Circular Economy

A circular economy is all about keeping materials in use for as long as possible. Custom recycled poly mailers are a key part of this model. By using recycled materials, you¨re contributing to a system where products are continually reused and repurposed. This approach conserves resources and minimizes waste. When you purchase recycled mailing bags bulk, you¨re not just buying packaging!you¨re supporting a more sustainable economic model.

5. Boosting Your Brand¨s Green Credentials

Today¨s consumers are increasingly drawn to brands that prioritize sustainability. By using custom recycled poly mailers, you¨re showcasing your commitment to the environment, which can enhance your brand¨s reputation. Eco-friendly packaging choices like recycled mailing bags wholesale resonate with customers who value green practices, making your business more attractive and trustworthy in their eyes.

6. Supporting Recycling Efforts

Demand for custom recycled poly mailers creates a positive ripple effect in the recycling industry. Increased use of recycled materials encourages more investment in recycling technology and infrastructure. This helps improve recycling processes and makes it easier to manage plastic waste effectively. When you choose recycled mailing bags, you¨re not just supporting your business¨s eco-friendly goals!you¨re also contributing to broader recycling initiatives.

7. Practical and Cost-Effective

Don¨t let the focus on sustainability overshadow the practicality of recycled mailing bags. These mailers are durable, offer the same level of protection as traditional plastic mailers, and are customizable to fit your brand¨s needs. They provide an effective and cost-efficient solution for shipping while aligning with your commitment to the environment. Bulk purchasing options like recycled mailing bags wholesale can also help you save money while making a positive environmental impact.

8. Encouraging Industry-Wide Change

By adopting custom recycled poly mailers, you¨re setting an example for others in your industry. As more businesses see the benefits of using recycled packaging, it creates a trend towards more sustainable practices across the board. Your choice can inspire other companies to follow suit, amplifying the positive impact on the environment and fostering a culture of responsibility.

Custom recycled poly mailers represent more than just a packaging choice!they are a step towards a more sustainable future. From reducing plastic waste and conserving resources to lowering carbon emissions and supporting recycling infrastructure, these mailers offer numerous environmental benefits.