모모If you몶re looking for the perfect tool to create complex and precise parts, look no further than plastic injection molds. This method of manufacturing has been around since 1872 when John Wesley Hyatt patented it as an alternative to ivory billiards balls. Throughout time, advancements in plastic injection molding have made this process even more valuable with today몶s tools producing a superior product at a much faster rate than ever before. Not only is plastic injection molding one of the most cost effective ways to produce high-quality parts in large volumes, but it also offers unparalleled precision compared to other techniques like casting or machining. In this post, we will take you through what exactly constitutes a 뫣plastic injection moldF and explore some of its advantages over other forming processes C so keep reading!In the industry, Aluminum mold tooling Has been a leader in the industry, but later came from behind but never arrogant, low-key to adhere to quality. https://super-ingenuity.cn/

모모

모모Rapid Molds

모모

모모Overview of Plastic Injection Molds and their Benefits

모모

모모Plastic injection molding is a manufacturing process that has revolutionized the way we produce plastic products. Injection molds are custom-made tools that produce different types of plastic products, from simple toys to complex car parts. The process begins by melting down raw plastic pellets in a hopper and then injecting the liquid plastic into the mold cavity. Once the plastic is cooled and hardened, the mold opens, and the finished product is ejected. The benefits of plastic injection molds are vast, including high efficiency and repeatability, cost-effectiveness, and the ability to produce complex shapes with precision. The process is ideal for mass production, making it a popular choice in industries such as automotive, aerospace, and medical. With technology advancements, the possibilities of injection molding are endless, offering a wide range of benefits that are unmatched by other manufacturing processes.

모모

모모The Design Process of Mold Making for Plastic Injection Molding

모모

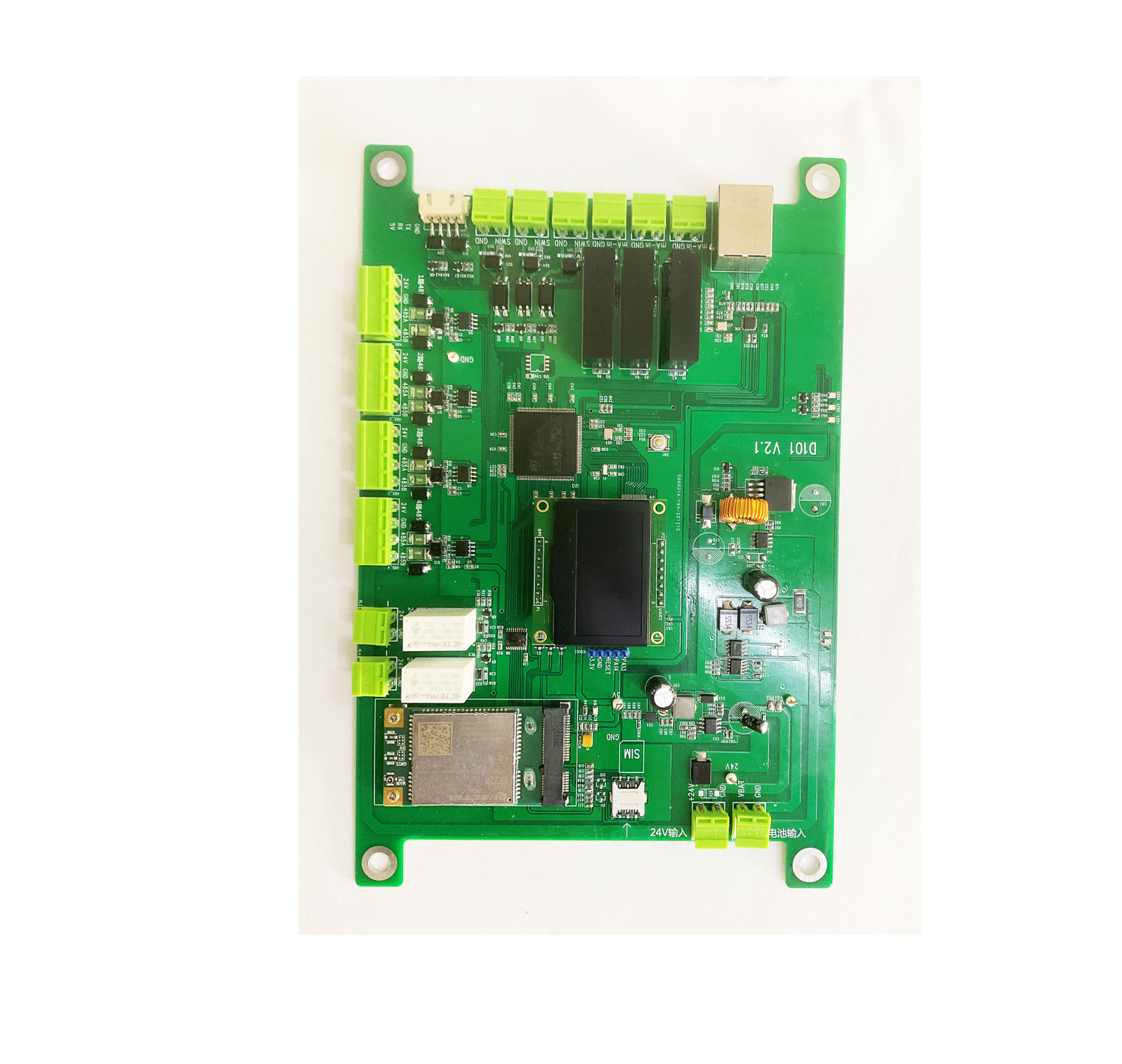

모모The creation of molds for plastic injection molding is an intricate design process that requires a wide array of skills and knowledge. Experienced designers must have a comprehensive understanding of the properties of various types of plastic, as well as an eye for detail and a knack for problem-solving. Even the slightest errors in design can lead to significant defects in the finished product, and the production process can be delayed or even come to a complete standstill if the mold isn몶t designed correctly. Despite the technical challenges involved in mold making, it몶s a fascinating process that involves a combination of artistic and scientific abilities. Molds are born from brainstorming sessions, sketches, 3D models, and prototypes, as designers work tirelessly to create the perfect mold for a specific product. Once the mold is finalized, the magic of plastic injection molding begins, bringing new products to life every single day.

모모

모모How to Choose the Right Materials for Your Plastic Injection Molds

모모

모모Choosing the right materials for your plastic injection molds can make all the difference in the quality and durability of your final product. With so many options available, it can be overwhelming to determine which materials will work best for your specific project. Factors such as application, environment, and budget all come into play when making this decision. It몶s important to do your research and work closely with a knowledgeable supplier who can guide you through the process. By taking the time to choose the right materials, you can ensure that your plastic injection molds will create high-quality products that meet your standards and satisfy your customers.

모모

모모In conclusion, when confronted with choosing the correct materials for your plastic injection molds, keep in mind that it takes careful consideration and knowledge of all factors that could potentially affect your design. From properly gauging the volume and wall thickness to taking into consideration cycle time, shot size and pressure for optimal performance C selecting the right material is essential for successful injection molding.

모모

모모As stated before, every successful mold is different and must address its own unique needs. Utilizing a combination of engineering insight and experienced tool makers can help you accelerate through the plastic injection process. Make sure to gather as much feedback across the board before deciding what works best to get your desired result safely and efficiently. Whether your company is in a crunch or planning ahead of time, Super-ingenuity will work hard to make sure you reach your goals in no time!